Back to Design Home Page

Evaluation and Selection of Concepts

Having generated possible solutions to a design

problem, how do we go about sorting out the ideas in order to arrive at

the best choice of concept? Techniques to help with this task have been

developed and this section will consider two such techniques. When using

these methods, attention must be given to overall engineering

feasibility and compliance with the Product Design

Specification (PDS). The techniques require an agreed set of

evaluation criteria and these must come from the PDS.

The two methods described here are:

- Weighted Objectives Method

- Method of Controlled Convergence

Weighted Objectives Method

This method requires a matrix to be completed, see below. A number of evaluation criteria are chosen and listed on the left of the matrix. The concepts are listed across the top. Next, a weighting factor is added to each criterion, i.e. it may be considered that function is more important than cost and a weighting (say between 1 and 10) can be added to make the appropriate adjustment. The matrix is completed by giving each concept a score out of (say) 5 and multiplying it by the weighting factor. An incomplete matrix is shown in the figure below.

Weighted Objectives Table

You will notice that in the above example, Function has been given a weighting of 7. Concept A has then been accessed regarding Function and is considered to function exactly as required. It has therefore been given the highest possible score of 5, making its total score for Function as 7 x 5 = 35.

Concept B has then been access for Function and it has been decided that it does not function as well as concept A. For that reason its Function has been scored a 2, making its total score for Function as 7 x 2 = 14.

This method is continued until all columns have been completed and summed to give a total score for each concept. The concept with the highest total score should be the one to develop into a final design.

This method, like many we come across in design is very subjective, relying on the evaluators engineering knowledge and skill.

Method of Controlled Convergence

This method was developed by S Pugh and first

published in 1981. It is covered in detail in his book, Total Design

- Integrated Methods For Successful Product Engineering (ISBN

0-201-41639-50)

these notes give just a brief overview.

Pugh claims that the purpose of evaluation is to

allow design principles to emerge visibly in a context and to be

articulated. He further claims that this method was devised on this

basis, out of a necessity to select actual concepts in practice with

greater certainty of success, which other methods fail to do. It is a

method which uses an evaluation matrix where the

evaluation criteria are

expressed on the vertical axis; concepts are depicted horizontally.

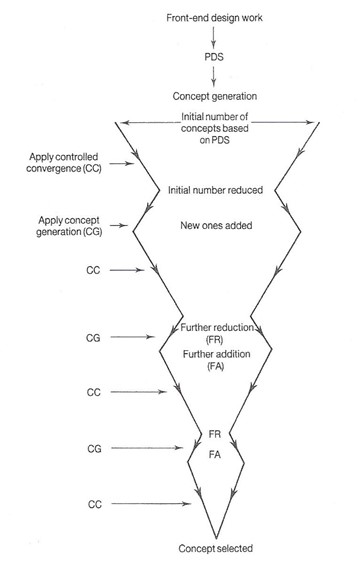

Method of Controlled Convergence - Taken from Pugh

The first thing to notice, as depicted in the above diagram, is that it is an iterative method, starting with a good number of initial concepts. These are evaluated to reveal, strong, mediocre and weak concepts. Most of the weak candidates will be eliminated reducing the overall number of concepts to a smaller number. Attempts are then made to improve the mediocre concepts to make them more acceptable, in this way increasing the number of concepts, however, to a number less that the original. In this way we see that it consists of a series of controlled convergences (CC) and controlled generations (CG). After 2 or 3 iterations a strong candidate normal becomes apparent.

This process is further explained with the use of the hypothetical evaluation matric shown below.

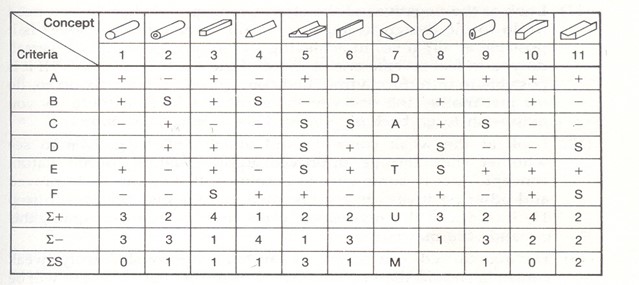

Hypothetical Controlled Convergence Evaluation Matrix - Taken from Pugh

On the above matrix it will be noticed that in the vertical left-hand column we have a set of evaluation criteria represented by capital letters A to F, these would have been taken from the PDS. They might include criteria such as; cost, maintenance, easy of use, easy of manufacture, ergonomics, etc. The generated concepts are shown across the top of the matrix and must have been developed to the same level of detail.

Once the matrix has been set up you then need to choose one of the concepts as a datum, this is an arbitrary choice, however if one of the concepts is already in existence it is probably a good choice for the datum.

For each of the evaluation criteria you then compare each of the concepts against the datum and record if it is considered better (+), the same (S) or inferior (-). Once the comparisons have been completed for all criteria you sum the +'s, the S's, and the -'s. Strong concepts will have many +'s, while weak candidates will have many -'s and will probably be discarded.

In the above matrix you will see that concept 3 is a very strong concept as it has 4 (+), 1 (-), and 1 (S). On the other hand concept 4 is very weak with 1 (+), 4 (-), and 1 (S), and would be eliminated. Concept 10 is a concept worth revisiting to see if it is possible to improve the 2 (-) and in this way generate a new concept for evaluation during the second phase of this method, where the second phase will develop a second matrix with a reduced number of concepts for reevaluation. The process is continued until a strong concept evolves.